Customer Customized Size Precision Steel Pipe

Application:Used for Mechanical Structures,Hydraulic Equipment,Automative Parts

Size: OD: 6mm-114mm,WT: 0.5mm - 60mm,LENGTH: 5.8/6/11.8/12m

Pipe Standard: EN 10305,ASTM A106-2006,BS 1139, DIN 2391,DIN 2445

Heat Treatment:NBK(+N),GBK(+A) ,BK(+C),BKW(+LC),BKS(+SR)

Classification :

Precision Steel Pipe

PRODUCT DETAILS

Description

Precision steel tube is a high-precision steel tube material processed by cold drawing or hot rolling. Because the inner and outer walls of precision steel pipes have no oxide layer, high pressure without leakage, high precision, high smoothness, cold bending without deformation, flaring, flattening without cracks, etc., they are mainly used to produce pneumatic or hydraulic components, such as cylinders or The oil cylinder can be a seamless tube or a welded tube.

Application

The internal and external diameter could control within +/- 0.01 mm. In the guarantee of anti-bending strength and torque strength same, the weight of precision pipe is lighter. It can be widely used in manufacturing precision machinery parts and engineering structure。

Size |

| Size Range | Tolerance |

OD | 6-325mm | -0.035 -- +0.045mm | |

ID | 2-250mm | ±0.035mm | |

WT | 1-32mm | depends on sizes | |

Length | random or fixed length | +0-3.5mm | |

Straightness | 0.15:1000, 0.4:1000, 0.5:1000 1:1000 or customized | ||

Surface Roughness | Ra 0.02—0.4μm | ||

Precision steel pipe size tolerances

For hot rolling precision steel pipe, tolerance of OD is +/- 0.1%.

For cold drawn precision pipe, tolerance allowed in below conditions:

Diameters 6mm to 10mm, normal tolerance condition +/- 0.2%, premium tolerance condition +/- 0.15%.

10mm to 30mm, normal tolerance condition +/- 0.4%, premium tolerance condition +/- 0.2%.

30mm to 50mm, normal tolerance condition +/- 0.45%, premium tolerance condition +/-0.3%.

For outer diameters above 50mm, normal tolerance condition +/- 0.1%, premium tolerance condition +/- 0.8%.

Specification&Standard

PRECISION CHREME-MOLYBDENUM STEEL TUBE

Standard | GB | ASTM | JIS | DIN |

GRADE | 15Cr | 5115 | SCR415 | 15Cr3 |

20Cr | 5120 | SCR420H | 20Cr4 | |

30Cr | 5130 | SCR430 | 28Cr4 | |

35Cr | 5132 | SCR430H | 34Cr4 | |

40Cr | 5140 | SCR440 | 41Cr4 | |

12CrMo | A-387CR | A-387CR | 13CrMo44 | |

15CrMo | 41.494.18 | 4125 | 16CrMo44 | |

20CrMo | 4125 | 4130 | 20CrMo44 | |

25CrMo | 4130 | SCR420H | 25CrMo4 | |

30CrMo | SCR420H | 4140 | 34CrMo4 | |

35CrMo | 4140 | 4140 | 42CrMo4 | |

42CrMo | A-387CR |

|

|

PRECISION ALLOY SEAMLESS STEEL TUBE

ASTM | A335-P1,A335-P2,A335-P12,A335-P11,A335-P22,A335-P9,A335-P5,A369-FP22,A213-T22,A213T11,A213-T12,A213-T2,A213-T1 |

GB | 16mo,CR2MO,CR5MO,12crmo,15crmo,12cr1mov, |

JIS | STPA12,STBA20,STPA22,STPA23,STPA24,STBA26, |

DIN | 15mo3,13crmo44,16CRMO44,10CRMO910,12CRMO195, |

Grade | Chemical Composition% | ||||

C | Si | Mn | P | S | |

20# | 0.17-0.24 | 0.17-0.37 | 0.35-0.65 | 0.035 | 0.035 |

45# | 0.42-0.50 | 0.17-0.37 | 0.50-0.80 | 0.035 | 0.035 |

SKTM13C-T(25Mn) | 0.22-0.29 | 0.17-0.37 | 0.70-1.00 | 0.035 | 0.035 |

27SiMn | 0.24-0.32 | 1.10-1.40 | 1.10-1.40 | 0.035 | 0.035 |

E355 | ≤0.22 | ≤0.55 | ≤1.6 | 0.025 | 0.025 |

Q345B | ≤0.2 | ≤0.5 | 1.00-1.60 | 0.030 | 0.030 |

Q345D | ≤0.2 | ≤0.5 | 1.00-1.60 | 0.030 | 0.030 |

SAE1026 | 0.22-0.28 | 0.15-0.35 | 0.60-0.90 | 0.040 | 0.050 |

Delivery condition | BKS Cold Drawn & Stress-Relieved | ||

Steel Grade | Rm MPa | ReH MPa | Elongation A5(%) |

ST45 | ≥520 | ≥375 | ≥15 |

ST52(E355) | ≥600 | ≥520 | ≥14 |

SAE1026 | ≥600 | ≥510 | ≥15 |

45# | ≥600 | ≥520 | ≥10 |

20# | ≥520 | ≥375 | ≥15 |

Delivery condition | BK Cold finished | |

Steel Grade | Rm MPa | Elongation A5(%) |

ST45 | ≥550 | ≥5 |

ST52(E355) | ≥640 | ≥5 |

SAE1026 | ≥640 | ≥5 |

45# | ≥640 | ≥5 |

20# | ≥550 | ≥8 |

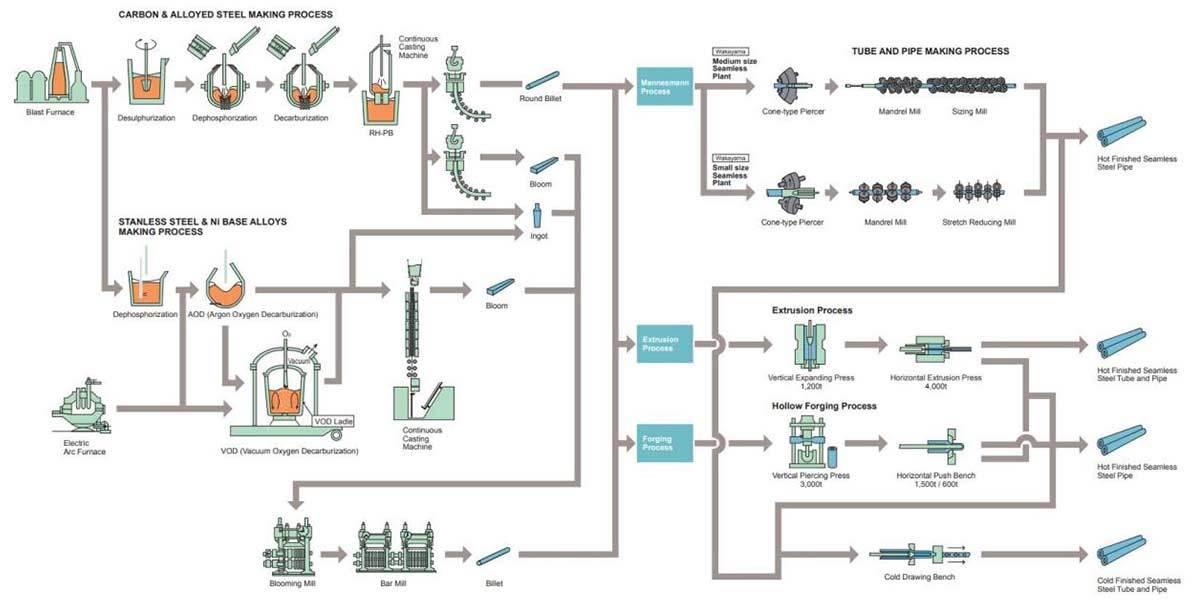

Process

Precision steel pipe manufacturing flow chart:

Raw Material Inspection – Remove Oxide Layer – Visual Inspection – Heating – Hot Rolling – Pickling and Passivation (Phosphating) – Grinding – Lubrication and Drying – Cold Rolling (Internal and external extraction) – Remove Oil – Ends Cutting – Inspection – Marking – Packing and Storage

As we know, most of precision steel pipe has cold drawn and hot rolled process. On the contrast, cold rolling will be more complicated. Not only the pipe need to be continuous rolled by three roller, but also the test have to be done after extrusion, so to guarantee the quality of the precision pipe materials.

Manufacturing methods of seamless precision pipe includes hot rolling and cold drawn. More over it could be manufactured in welding processes.

Precision steel pipe manufacturing flow chart:

Raw Material Inspection – Remove Oxide Layer – Visual Inspection – Heating – Hot Rolling – Pickling and Passivation (Phosphating) – Grinding – Lubrication and Drying – Cold Rolling (Internal and external extraction) – Remove Oil – Ends Cutting – Inspection – Marking – Packing and Storage

As we know, most of precision steel pipe has cold drawn and hot rolled process. On the contrast, cold rolling will be more complicated. Not only the pipe need to be continuous rolled by three roller, but also the test have to be done after extrusion, so to guarantee the quality of the precision pipe materials.

Manufacturing methods of seamless precision pipe includes hot rolling and cold drawn. More over it could be manufactured in welding processes.

Packing

20ft GP:5898mm(Length)x2352mm(Width)x2393mm(High) 24-26CBM

40ft GP:12032mm(Length)x2352mm(Width)x2393mm(High) 54CBM

40ft HC:12032mm(Length)x2352mm(Width)x2698mm(High) 68CBM

In bundle,plastic bags,thin film,wooden pallet,standard seaworthy export packing or as customer demands

Packaging and delivery

The company has the Shandong Dayang Steel Pipe Production Base Warehouse Area, Dadong Steel Pipe City Boutique Goods Yard Sales Area, etc., with an annual inventory of 70,000 tons.The annual round steel trade volume is 650,000 tons, with 50,000 tons of spot goods throughout the year, and the output value is about 6 billion yuan. The factory has eight pipe expansion production lines, mainly producing 300-1500mm outer diameter, with an annual output of 80,000 tons.

Customer visit

Adhering to the tenet of "strict management, good reputation, strong strength, and high-quality service", the company serves customers and friends at home and abroad with high standards of scientific environmental protection, professional innovation, and currently exports to more than 150 countries and regions in Europe, America, South America, the Middle East, Asia, etc., and the products are well received by everyone!

Factory

The factory focuses on the research and development and manufacturing of seamless steel pipes, oil casing processing for oil fields and gas cylinder steel pipe products. It currently has one hot-rolled seamless steel pipe production line. The production process of the hot-rolled seamless steel pipe production line adopts conical perforation, precision pipe rolling and three-roller micro-tension sizing. The production specifications are: Φ50-Φ273mm, wall thickness: 4.5-40mm, and the online equipped ultrasonic flaw detection system, eddy current flaw detection system and other product detection systems have reached the industry leading level.

相关产品

Related products