Z-shaped steel sheet pile construction process

Classification :

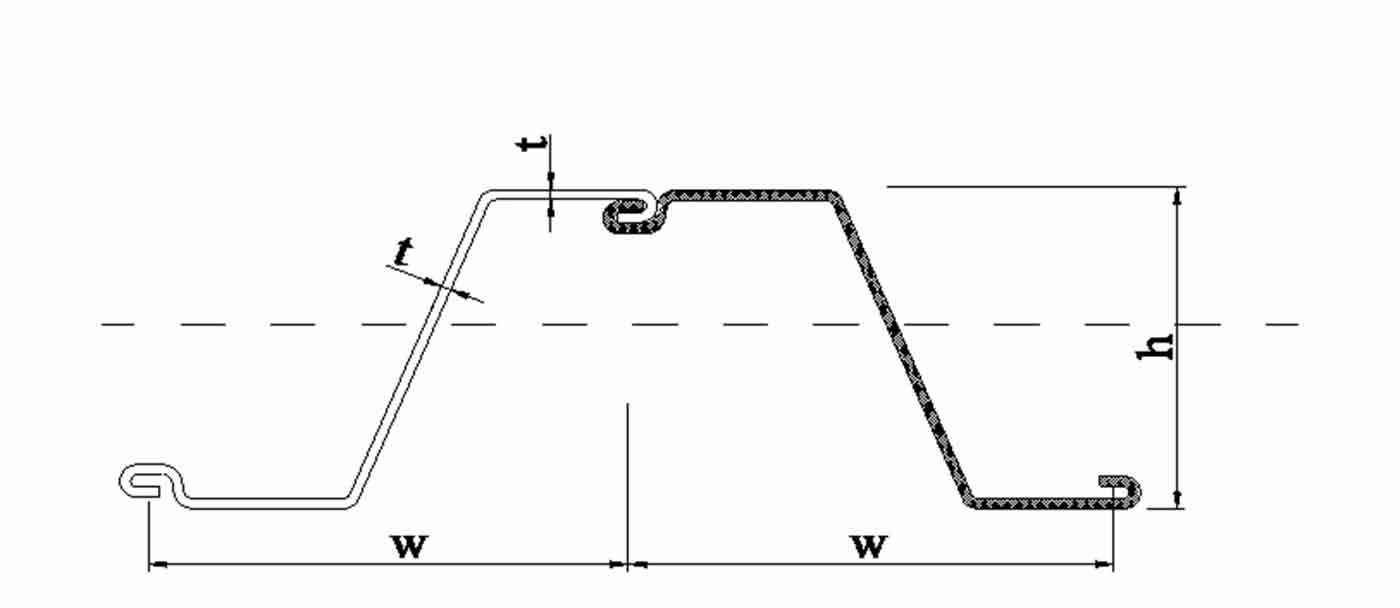

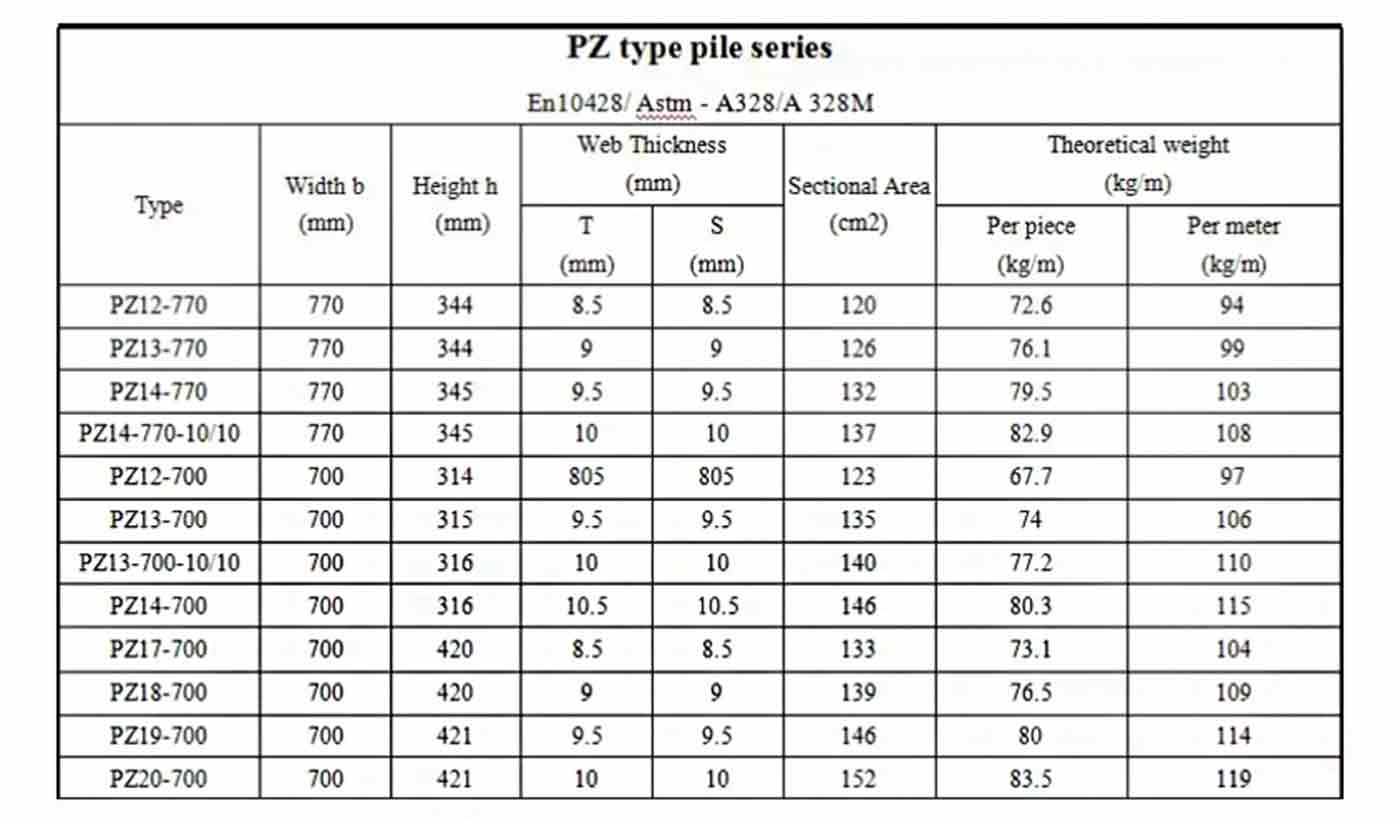

Shaped Sheet Piles

PRODUCT DETAILS

The Z-shaped steel sheet pile is driven using vibration driving method, and the pile is pulled out using a 50 ton crawler crane combined with a vibration hammer. The construction steps of Z-shaped steel sheet pile are as follows: setting up the guide pile frame → cleaning the Z-shaped steel sheet pile → inserting and driving the Z-shaped steel sheet pile → setting internal support → plugging → mud suction → hardening the base → construction of the bearing platform and pier body → pulling out the Z-shaped steel sheet pile.

Packaging and delivery

The company has the Shandong Dayang Steel Pipe Production Base Warehouse Area, Dadong Steel Pipe City Boutique Goods Yard Sales Area, etc., with an annual inventory of 70,000 tons.The annual round steel trade volume is 650,000 tons, with 50,000 tons of spot goods throughout the year, and the output value is about 6 billion yuan. The factory has eight pipe expansion production lines, mainly producing 300-1500mm outer diameter, with an annual output of 80,000 tons.

Customer visit

Adhering to the tenet of "strict management, good reputation, strong strength, and high-quality service", the company serves customers and friends at home and abroad with high standards of scientific environmental protection, professional innovation, and currently exports to more than 150 countries and regions in Europe, America, South America, the Middle East, Asia, etc., and the products are well received by everyone!

Factory

The factory focuses on the research and development and manufacturing of seamless steel pipes, oil casing processing for oil fields and gas cylinder steel pipe products. It currently has one hot-rolled seamless steel pipe production line. The production process of the hot-rolled seamless steel pipe production line adopts conical perforation, precision pipe rolling and three-roller micro-tension sizing. The production specifications are: Φ50-Φ273mm, wall thickness: 4.5-40mm, and the online equipped ultrasonic flaw detection system, eddy current flaw detection system and other product detection systems have reached the industry leading level.

相关产品

Related products