Drill Pipe

Size:OD: 60.32mm-168.28mm,WT: 6.45-12.7mm,LENGTH: R1, R2, R3

Pipe Standard:API 5DP E75, X95, G105, S135

Upset Style:IU, EU, IEU

Connection:NC26 - NC50, 5 1/2FH, 6 5/8FH

Internal coating:TK34,TC2000, Arnco 100XT, 200XT, 300XT

InquirySend Email To Us

Classification :

Drill Pipe

PRODUCT DETAILS

Description

Drill pipes are long tubular sections of pipe that make up the majority of the drill string. They are typically a 31 foot long section of tubular pipe but may be anywhere from 18 to 45 feet in length.

Heavy weight drill pipe (HWDP) is a tubular pipe that adds weight or acts as a transitional piece in the drill string. As a transitional section of the drill string, it is placed between the drill collar and standard drill pipe to reduce fatigue failures. In other applications the HWDP is used as an additional weight to weigh down the drill string.

Heavy weight drill pipe is a medium-weight drilling pipe, (referred standards in API SPEC 7-1). It has bigger wall thickness than common drilling pipe and smaller than drill collar.

Drill collars are a component of the drill string that makes up part of the BHA. They are thicker-walled, heavier, and more rigid than drill pipes and are primarily used to weigh down the drill bit while dampening vibration and impact forces.

Drill Pipe:2-3/8" to 7-5/8" OD, Range 2 and 3

Heavy Weight pipe:2-3/8" to 6-5/8" OD, Range 2 and 3

Drill Collars:2-7/8" to 14"

Grades: E75, X95, G105, S135

Connection threads:NC26, NC31, NC38, NC40, NC46, NC50, 5 1/2FH.6 5/8FH.

Internal Upset: IU, EU, IEU

Specification&Standard

|

Size designation |

Calculated weight |

Tool joint designation |

Calculated weight |

grade |

Wall thickness |

Upset ends |

||

|

in |

1b/ft |

Kg/m |

in |

mm |

||||

|

2 3/8 |

6.65 |

NC26 |

6.26 |

9.32 |

E.X.G.S |

0.28 |

7.11 |

EU |

|

2 7/8 |

10.4 |

NC31 |

9.72 |

14.48 |

E.X.G.S |

0.362 |

9.19 |

EU |

|

3 1/2 |

13.3 |

NC38 |

12.31 |

18.34 |

E.X.G.S |

0.368 |

9.35 |

EU |

|

3 1/2 |

15.5 |

NC38,NC40 |

14.63 |

21.79 |

E.X.G.S |

0.449 |

11.4 |

EU |

|

4 |

14 |

NC40,NC46 |

12.93 |

19.26 |

E.X.G.S |

0.33 |

8.38 |

IU,EU |

|

4 1/2 |

16.6 |

NC46,NC50 |

14.98 |

22.31 |

E.X.G.S |

0.337 |

8.56 |

EU,IEU |

|

4 1/2 |

20 |

NC46,NC50 |

18.69 |

27.84 |

E.X.G.S |

0.43 |

10.92 |

EU,IEU |

|

5 |

19.5 |

NC50,NC52 |

17.93 |

26.71 |

E.X.G.S |

0.362 |

9.19 |

IEU |

|

5 |

25.6 |

NC50,5 1/2FH |

24.03 |

35.79 |

E.X.G.S |

0.5 |

12.7 |

IEU |

|

5 1/2 |

21.9 |

5 1/2FH |

19.81 |

29.51 |

E.X.G.S |

0.361 |

9.17 |

IEU |

|

5 1/2 |

24.7 |

5 1/2FH |

22.54 |

33.57 |

E.X.G.S |

0.415 |

10.54 |

IEU |

|

6 5/8 |

25.2 |

6 5/8FH |

22.19 |

33 |

E.X.G.S |

0.33 |

8.387 |

IEU |

|

6 5/8 |

27.7 |

6 5/8FH |

24.21 |

41 |

E.X.G.S |

0.362 |

9.19 |

IEU |

Dimension Tolerances

|

|

Tolerance |

|

|

D Drill-pipe-body Outside Diameter |

Pipe body

|

D≤101.60mm,±0.79mm |

|

D≥114.30mm,+1.0%, -0.5%D |

||

|

Drill-pipe-body behind the Meu |

D≥60.32~≤88.90mm,+2.38%, -0.79%D |

|

|

D>88.90~≤127.00mm,+2.78mm, -0.75%D |

||

|

D>127.00~≤168.28mm,+3.18mm,-0.75%D |

||

|

Wall Thickness |

0, -12.5%t |

|

API SPEC 5DP specifies the technical delivery conditions for steel drill-pipes with upset pipe-body ends and weld-on tool joints for use in drilling and production operations in petroleum and natural gas industries for three product specification levels (PSL-1, PSL-2 and PSL-3). PS-1 specifies wall thickness, impact strength, and yield strength requirements specific to the material grade. Specification levels PL-2 / PL-3 have additional mandatory requirements.

Chemical Composition

|

|

steel grade |

P (%) |

S (%) |

|

≤ |

≤ |

||

|

Pipe body |

E |

0.030 |

0.020 |

|

X, G, S |

0.020 |

0.015 |

|

|

Tool Joint |

0.020 |

0.015 |

|

Mechanical Properties

|

Chemical composition requirements |

||

|

Pipe body |

Phosphorus max. % |

Sulfur max. % |

|

Pipe body grade E |

0.030 |

0.020 |

|

Pipe body grades X, G and S |

0.020 |

0.015 |

|

Tool joint |

0.020 |

0.015 |

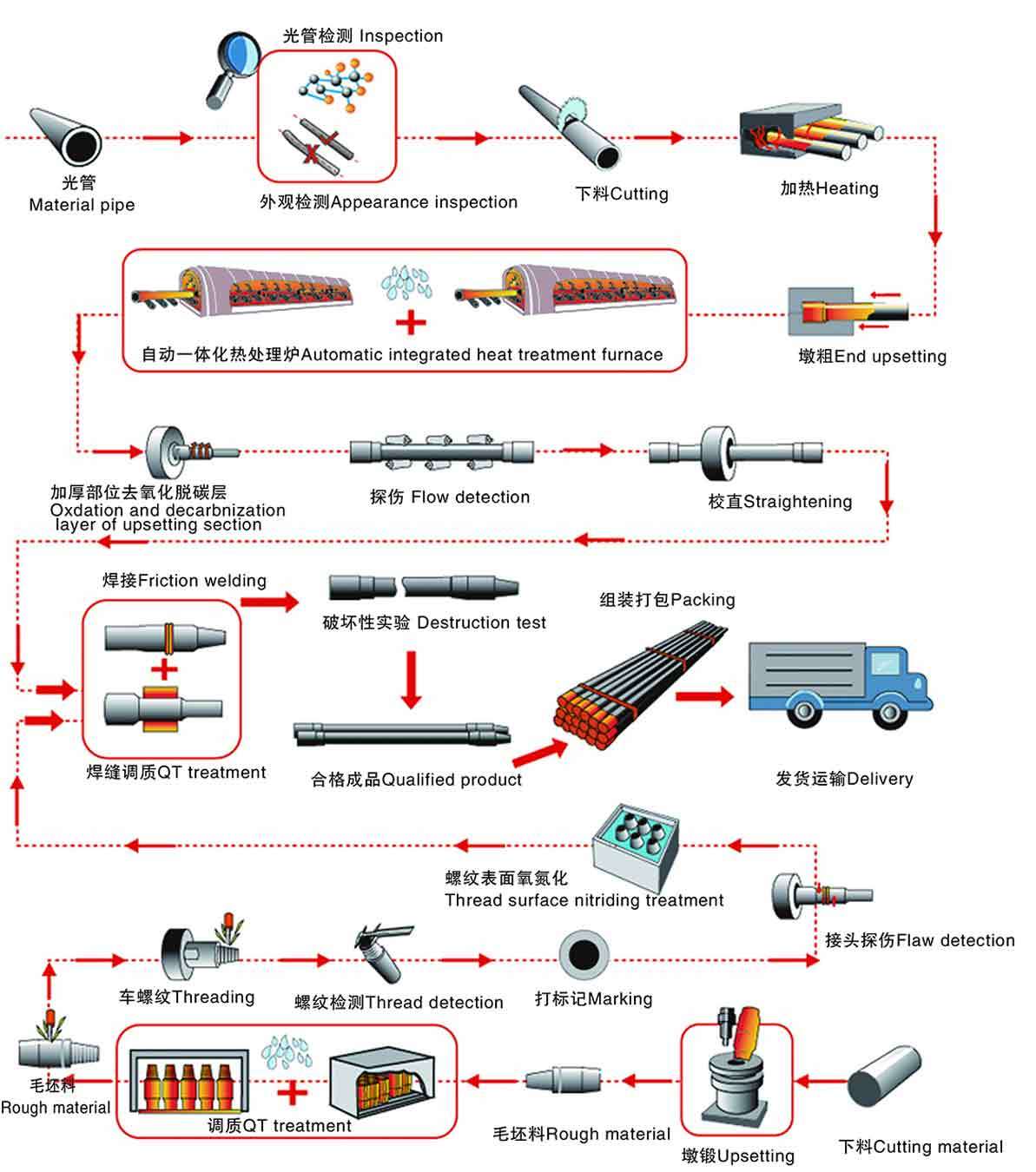

Process

Packaging and delivery

The company has the Shandong Dayang Steel Pipe Production Base Warehouse Area, Dadong Steel Pipe City Boutique Goods Yard Sales Area, etc., with an annual inventory of 70,000 tons.The annual round steel trade volume is 650,000 tons, with 50,000 tons of spot goods throughout the year, and the output value is about 6 billion yuan. The factory has eight pipe expansion production lines, mainly producing 300-1500mm outer diameter, with an annual output of 80,000 tons.

Customer visit

Adhering to the tenet of "strict management, good reputation, strong strength, and high-quality service", the company serves customers and friends at home and abroad with high standards of scientific environmental protection, professional innovation, and currently exports to more than 150 countries and regions in Europe, America, South America, the Middle East, Asia, etc., and the products are well received by everyone!

Factory

The factory focuses on the research and development and manufacturing of seamless steel pipes, oil casing processing for oil fields and gas cylinder steel pipe products. It currently has one hot-rolled seamless steel pipe production line. The production process of the hot-rolled seamless steel pipe production line adopts conical perforation, precision pipe rolling and three-roller micro-tension sizing. The production specifications are: Φ50-Φ273mm, wall thickness: 4.5-40mm, and the online equipped ultrasonic flaw detection system, eddy current flaw detection system and other product detection systems have reached the industry leading level.

相关产品

Related products